How Chain Lubricant Thickness Affects System Performance

페이지 정보

조회 2회 작성일 25-12-17 23:32

본문

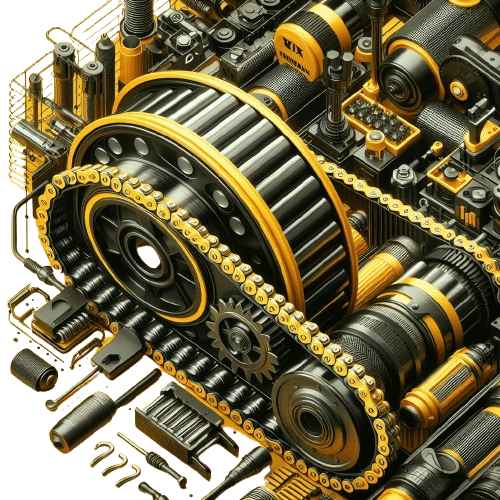

The flow characteristics of chain lubricant plays a essential role in determining how efficiently a chain system functions. When a lubricant is too thick or has resistant flow, it increases internal resistance within the chain links and in the roller-bushing contacts. This increased resistance forces the drive system to exert more effort, consuming more energy and reducing overall mechanical efficiency. On the other hand, if the lubricant is insufficiently viscous, it may not sustain a consistent barrier between moving parts. This can cause unprotected metal friction, increased wear, and progressively rising resistance as the components lose integrity.

The ideal viscosity mediates between opposing demands. It must be sufficiently viscous to preserve an effective barrier under working stress and heat but low enough in resistance to allow smooth movement without unwanted resistance. Manufacturers often recommend specific lubricant weights based on the chain type, chain velocity, and ambient factors. For example, in low-temperature environments, a lighter oil may be recommended to prevent startup stiffness, while in elevated heat or high-torque scenarios, a higher viscosity lubricant may be essential to maintain protective integrity.

Using a lubricant with the unsuitable grade can also impact the ability of the lubricant penetrates the chain’s internal components. A lubricant that is too viscous may be unable to penetrate the critical contact areas, exposing components to wear. A lubricant that is too thin may be slung away by rotation before it can provide lubrication. Both scenarios cause reduced efficiency and accelerated wear.

Proper upkeep and appropriate selection the optimal fluid thickness for your unique operating environment can dramatically boost performance. Over time, even the high-quality fluid breaks down or فروش زنجیر صنعتی collects contaminants, so refreshing with the proper grade at scheduled times ensures the chain continues to operate smoothly and with reduced parasitic drag. In industrial or cycling applications, where performance is paramount, choosing the optimal fluid grade is not just about longevity—it’s about unlocking full potential.