Essential Safety Guidelines for Industrial Chain Operations

페이지 정보

조회 5회 작성일 25-12-18 10:33

본문

During industrial chain usage safety should always be the top priority. They are built to manage substantial weights and intense mechanical stress, but they can become dangerous if not handled properly. Never skip the mandatory chain inspection prior to operation. Look for signs of wear such as excessive link spacing, cracks, oxidation, or detached connectors. Minor damage may trigger catastrophic breakdowns when stressed, so never ignore any damage.

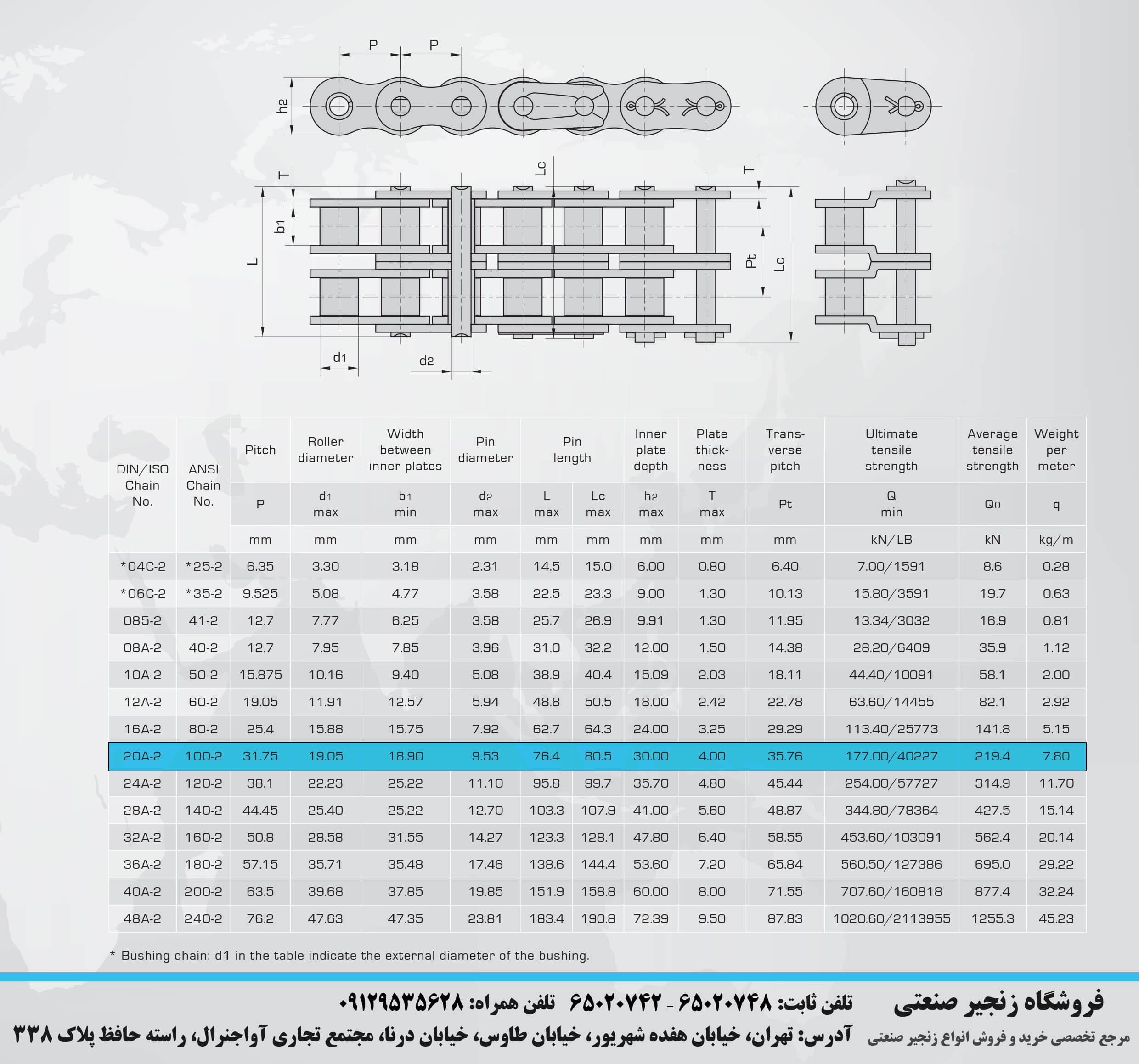

Make sure you are using the right chain for the job. Each chain has a designated load capacity, and going beyond the rated capacity risks sudden rupture. Verify load ratings against operational demands. Using a chain that is too light for the load is one of the most common causes of accidents.

Always use proper PPE. This includes heavy duty gloves to protect your hands from sharp edges and pinch points, safety glasses to shield your eyes from sparks and fragments, and protective footwear to protect your feet in case of a falling load. Keep sleeves, ties, and accessories secured away from machinery.

Never stand directly under a suspended load. Even if the chain appears secure, sudden ruptures are possible. Position yourself off-axis and at a minimum safe radius. Apply correct hoisting methods and confirm the load is evenly distributed and firmly connected.

Ensure the chain is free of contaminants and well-oiled. Contaminants increase friction and compromise structural integrity. Adhere strictly to the specified lubrication schedule and product. A well lubricated chain not only lasts longer but also operates more smoothly and safely.

Industrial chain work must be performed by certified individuals. If a chain needs repair or replacement, never modify it without official authorization. Altering the chain structure destroys its engineered strength and invalidates certifications.

Keep chains in a moisture-free, فروش زنجیر صنعتی debris-free space. Moisture and exposure to chemicals can cause rust and degradation. Store vertically to prevent deformation.

Implement a consistent inspection and servicing routine. Keep detailed records of inspections, repairs, and replacements. This helps assess long-term performance trends and supports audit readiness.

By following these practices, you reduce the risk of accidents and extend the life of your equipment. Safety is not just a rule—it is a responsibility that protects everyone on the job site.